ISO 9001 Certification

ISO procedures and quality control are followed from start to finish, ensuring that parts are on-spec, scrap is minimized, and the order is documented each step of the way. Our internal quality control process has placed us in a preferred vendor relationship with some of North America’s largest and most demanding industrial companies.

Relationships

The list of our top customers hasn’t changed much in the last ten years. That’s because we recognize that quality work is not only necessary, it’s a given. Our strength comes from developing relationships based on strong communication and flexibility–grounded on our core values of Teamwork, Servant Leadership, and Trust. These values are foundational to our business and culture.

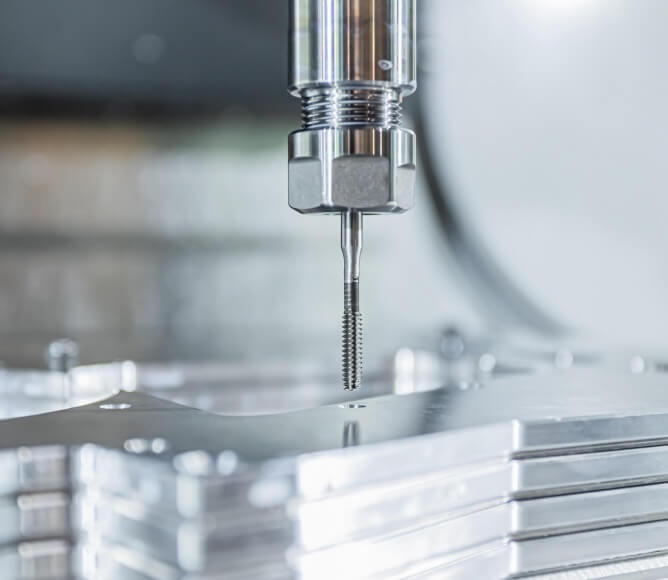

Innovation and Technology

State of the art machines and manufacturing engineering alongside the most up to date Mastercam programming software are the tools we use to serve our customers and meet their ever-changing needs. We support all our customers’ needs in Lean Manufacturing, JIT delivery, inventory control and documentation.

Our ERP system ensures that we can provide an accurate forecast of capacity and delivery timelines while maintaining efficiencies and inventory control. Paperless accounting systems and continuous improvements have contributed to our pursuit of excellence.

Pursuit of Excellence

We have a dedicated team of experienced Journeyman and skilled operators who take great pride in producing quality parts on-time for our customers. Foundational to our success is teamwork and every role is critical to our success in serving our customer needs.

Quality parts are not enough – documentation and traceability are key to ensuring that our customers can be confident in the materials and processes that go into our parts.